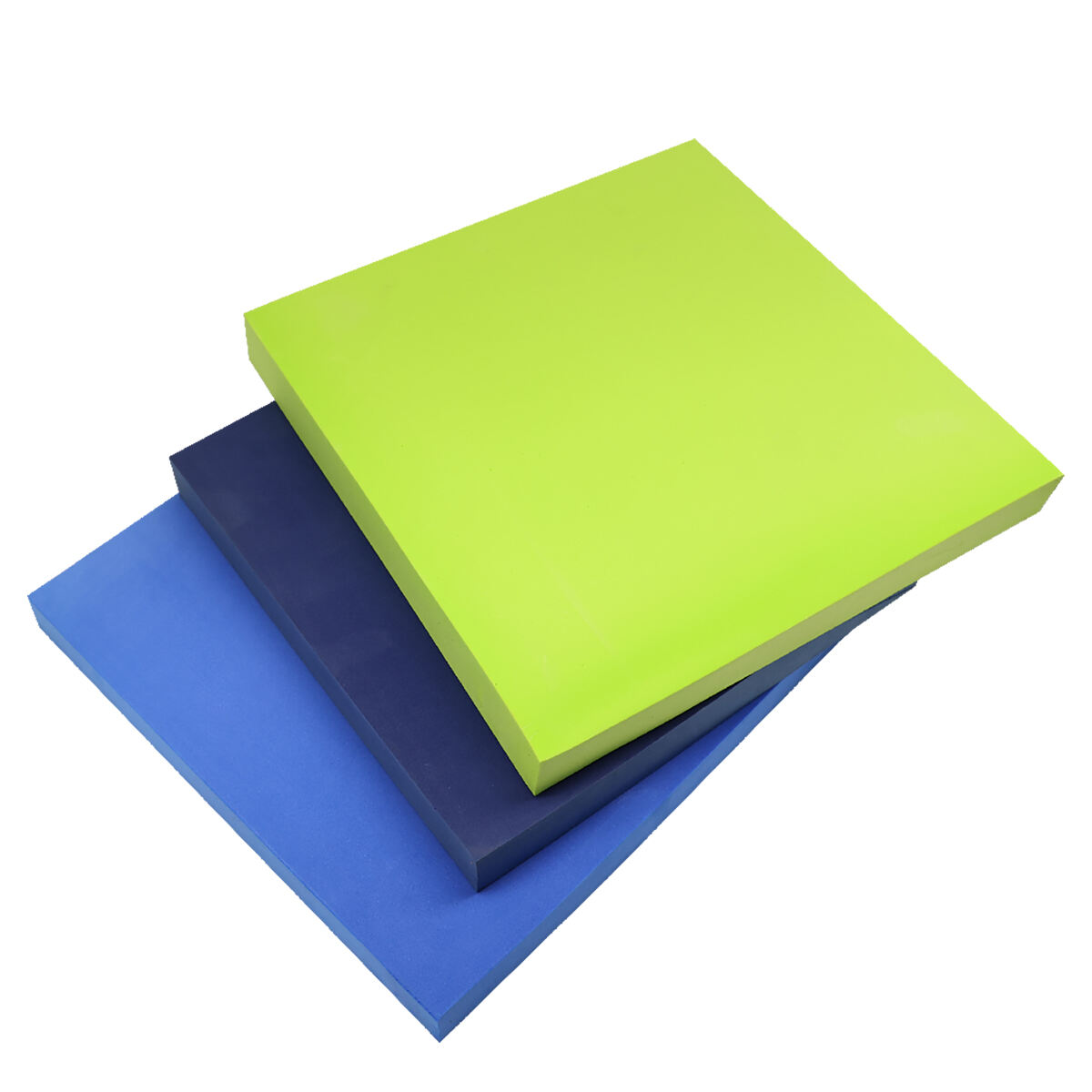

PE foam material, derived from polyethylene, is a versatile and highly functional substance with a wide array of applications across industries. This foam is produced through a foaming process that introduces gas into the polyethylene matrix, creating a cellular structure that can be tailored to have different properties. Open-cell PE foam offers excellent breathability and conformability, making it suitable for applications that require soft cushioning and moisture absorption, such as in sports gear padding and filtration materials. Closed-cell PE foam, on the other hand, provides superior moisture resistance, buoyancy, and durability, making it ideal for marine applications, floatation devices, and industrial insulation. The material's chemical resistance, low thermal conductivity, and dimensional stability contribute to its popularity in sectors like construction, automotive, and electronics. In construction, PE foam is used for weatherstripping, thermal insulation, and soundproofing, improving building energy efficiency and occupant comfort. In the automotive industry, it serves as insulation, cushioning, and vibration dampening material. With continuous advancements in manufacturing techniques, PE foam material can be engineered with enhanced properties, such as anti-static, flame retardant, and UV-resistant features, meeting the evolving demands of modern industries.