Introduction

EVA foam, or ethylene-vinyl acetate foam, has become an indispensable material across countless industries due to its unique combination of cushioning, durability, and versatility. From the insoles of your running shoes to protective gym flooring and precision toy packaging, EVA foam is everywhere. However, not all EVA foam is created equal. With a vast array of densities, formulations, and processing options available, selecting the right material can be a complex decision that directly impacts the performance, safety, and cost-effectiveness of your final product.

For over four decades, the SANSD Group, through QUANZHOU WEFOAM TRADING CO., LTD, has stood at the forefront of advanced foam manufacturing. This guide distills our extensive expertise into a comprehensive roadmap to help you navigate the critical factors in choosing the perfect EVA foam for your specific application in 2025 and beyond.

Understanding EVA Foam: Core Properties and Types

Before delving into selection criteria, it’s essential to understand what EVA foam is and its fundamental characteristics. EVA is a closed-cell, copolymer foam known for its excellent flexibility, chemical resistance, and low-temperature toughness. Its properties can be finely tuned during manufacturing, leading to several primary types:

1. Standard EVA Foam: The most common type, offering a good balance of softness, elasticity, and durability. It is widely used in sports equipment, packaging, and crafts.

2. PE-EVA Blends: By blending EVA with Polyethylene (PE), manufacturers can enhance certain properties. These foams often exhibit improved rigidity, dimensional stability, and water resistance, making them suitable for marine decking and industrial mats.

3. Cross-Linked EVA Foam: This type undergoes an additional chemical or physical cross-linking process. The result is a foam with superior mechanical strength, resilience, and heat resistance. It is ideal for high-performance applications like premium sports shoe midsoles, automotive parts, and gym pads that must withstand repeated heavy impact.

4. Specialty Foams (TPE & EPDM): While EVA is versatile, other polymers like Thermoplastic Elastomers (TPE) and Ethylene Propylene Diene Monomer (EPDM) offer distinct advantages. TPE foams provide exceptional soft-touch feel and recyclability, whereas EPDM foam is renowned for its outstanding weather, ozone, and UV resistance, perfect for outdoor applications.

Key Factors to Consider When Choosing EVA Foam

Making an informed choice requires a systematic evaluation of your project’s needs against the material’s properties.

1. Density and Hardness (Durometer)

Density (measured in kg/m³ or lbs/ft³) and hardness (measured on the Shore scale, often Shore C) are the most critical starting points.

Low Density (e.g., 30-80 kg/m³): Softer, more compressible. Ideal for lightweight padding, soft toy components, and protective packaging for delicate items.

Medium Density (e.g., 80-150 kg/m³): Offers a balance of cushioning and support. Commonly used for yoga mats, standard shoe insoles, and general-purpose mats.

High Density (e.g., 150-300+ kg/m³): Firm, durable, and highly resilient. Essential for heavy-duty applications like marine decking, gym flooring underlay, high-impact sports equipment, and industrial padding.

Choosing Tip: Define the required level of cushioning versus support. A gym pad for weightlifting needs high density to prevent bottoming out, while a child’s play mat benefits from medium density for safe comfort.

2. Elasticity and Compression Set

Elasticity refers to the material’s ability to return to its original shape after deformation. Compression set is a specific test that measures permanent deformation after prolonged compression. A low compression set percentage is crucial for applications where the foam must maintain its shape and functionality over time, such as in recurring-use packaging or footwear that bears constant weight.

3. Cell Structure: Open vs. Closed Cell

EVA is predominantly closed-cell foam, meaning its individual cells are sealed off from each other. This structure makes it water-resistant, buoyant, and prevents moisture absorption—key for marine applications, outdoor products, and hygiene-sensitive uses like sports mats. Open-cell foams (more common in other materials) are breathable and more compressible but absorb liquids.

4. Chemical and Environmental Resistance

Consider the operational environment:

Water & Moisture: Closed-cell EVA performs excellently.

Oils & Solvents: Standard EVA has fair resistance; specialized formulations may be needed for harsh chemicals.

UV Radiation: Standard EVA can degrade in prolonged sunlight. For outdoor applications like luggage or marine decking, specify UV-stabilized EVA or consider EPDM foam for superior long-term weather resistance.

Temperature Range: Ensure the foam’s operational temperature range suits your application, especially for items exposed to extreme cold or heat.

5. Color, Finish, and Custom Processing

The aesthetic and functional finish of the foam is vital for end-user appeal and performance.

Color: EVA foam can be manufactured in virtually any color. Consider colorfastness, especially for outdoor products.

Surface Texture: Options range from smooth to embossed patterns (e.g., diamond plate, pebble) which can enhance grip and aesthetic value.

Lamination: For enhanced durability and a premium finish, EVA foam can be laminated with various fabrics, leathers, or films. This is common in luggage, high-end yoga mats, and orthopedic products.

Fabrication: Partner with a supplier like Wefoam that offers comprehensive custom processing services—including precision CNC cutting, die-cutting, molding, thermoforming, and drilling. This ensures the foam components arrive ready for assembly, reducing your production complexity.

Application-Specific Selection Guidelines

Sports Shoes & Insoles: Focus on cross-linked EVA with a medium to high density and excellent compression set for long-lasting cushioning and energy return.

Toys & Crafts: Safety is paramount. Choose non-toxic, odorless foams in vibrant colors. Softer densities are often suitable.

Gym & Exercise Mats: Prioritize density for support, a comfortable surface texture (often laminated PE or fabric), and ease of cleaning. TPE foam is a popular, eco-friendly alternative here.

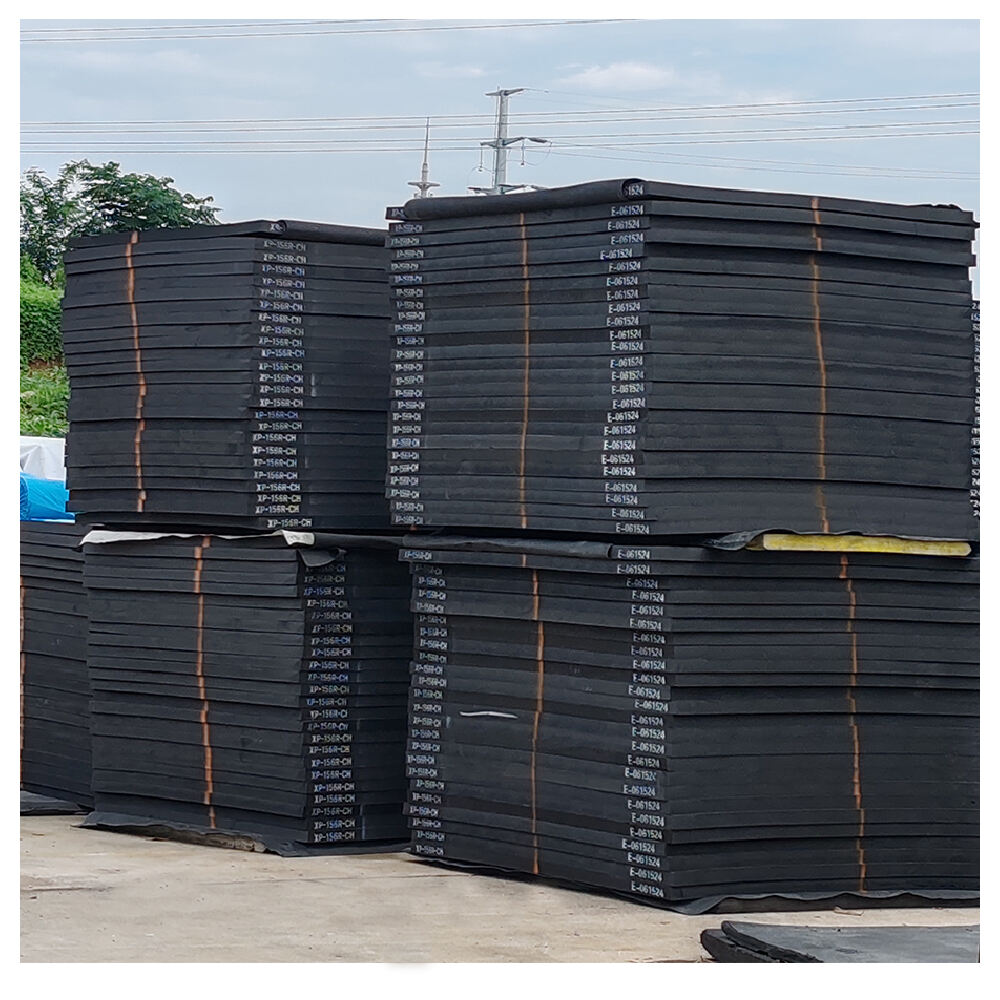

Protective Packaging: Match the foam’s cushioning curve to the product’s fragility. Custom-cut foam inserts from oversized foam boards provide impeccable protection for electronics, instruments, or industrial parts.

Marine & Outdoor Decking: This demands high-density, UV-stabilized foam with superb slip resistance (often through embossing). PE-EVA blends or EPDM foam offer optimal durability against the elements.

Industrial Applications: Define the primary need: shock absorption, vibration damping, gasketing, or insulation. Chemical and temperature resistance will often dictate the specific polymer blend.

Partnering with the Right EVA Foam Manufacturer

Your supplier’s capability is as important as the material specifications.

Technical Expertise: Choose a manufacturer with deep R&D and application knowledge, capable of guiding you through the selection process.

Quality Consistency: Ensure they have rigorous quality control systems to deliver uniform density, cell structure, and performance batch after batch.

Customization Scope: Can they provide not just raw material (oversized foam boards, rolls) but also deliver custom processed finished or semi-finished components?

Global Experience: A supplier accustomed to serving diverse international markets will better understand regional standards, cultural preferences, and logistical needs.

Conclusion

Choosing the right EVA foam is a strategic decision that balances technical parameters with practical application needs and cost considerations. By systematically evaluating factors such as density, cell structure, environmental resistance, and required custom processing, you can unlock the full potential of this remarkable material. As innovations in polymer blends and sustainable formulations continue to emerge in 2025, partnering with an experienced, technically adept manufacturer like QUANZHOU WEFOAM TRADING CO., LTD becomes your greatest asset. Our four decades of lineage within the SANSD Group ensure that you receive not just a product, but a comprehensive foam solution engineered for your success.

FAQ (Frequently Asked Questions)

Q1: What is the main difference between EVA foam and PE foam?

A1: While both are closed-cell foams, EVA (ethylene-vinyl acetate) is generally softer, more flexible, and has better elasticity and rubber-like feel. PE (polyethylene) foam tends to be more rigid, crinkly, and offers superior moisture and chemical resistance. The choice depends on whether you prioritize cushioning and flexibility (EVA) or structural rigidity and barrier properties (PE). Many advanced foams, like those from Wefoam, are blends that optimize the benefits of both.

Q2: How do I determine the correct density of EVA foam for my project?

A2: The correct density is primarily determined by the load-bearing requirement and desired feel. Conduct a simple compression test with samples: the foam should compress adequately to provide cushioning but not so much that it “bottoms out” (fully compresses) under typical load. For technical applications, consult with your foam manufacturer’s engineering team who can recommend densities based on pressure-distribution calculations and industry standards for your specific use case.

Q3: Is EVA foam environmentally friendly and recyclable?

A3: Standard EVA foam is not biodegradable, but it is recyclable. The challenge lies in establishing efficient collection and recycling streams. Leading manufacturers are actively developing more sustainable solutions, including bio-based EVA derivatives, TPE foams which are easier to recycle in certain streams, and offering take-back programs for production waste. Always inquire about the latest eco-friendly options available from your supplier.

Q4: Can EVA foam be used for outdoor applications?

A4: Yes, but with important specifications. For long-term outdoor use, you must select UV-stabilized EVA foam to prevent degradation and cracking from sunlight. For extreme weather conditions, constant moisture exposure, or high ozone environments, EPDM foam is often a superior choice due to its innate exceptional weather and ozone resistance.

Q5: What are the advantages of opting for custom processing from my EVA foam supplier?

A5: Opting for in-house custom processing (like cutting, lamination, molding) offers significant advantages: 1. Precision: Manufacturer-level cutting ensures tight tolerances. 2. Cost Efficiency: It reduces your in-house labor, tooling, and waste disposal costs. 3. Speed: Streamlines your supply chain and speeds up production. 4. Quality Assurance: The finished component is produced under controlled conditions by foam experts, ensuring integrity. It transforms a raw material purchase into a tailored, value-added component ready for assembly.

Table of Contents

- Introduction

- Understanding EVA Foam: Core Properties and Types

- Key Factors to Consider When Choosing EVA Foam

- Application-Specific Selection Guidelines

- Partnering with the Right EVA Foam Manufacturer

- Conclusion

-

FAQ (Frequently Asked Questions)

- Q1: What is the main difference between EVA foam and PE foam?

- Q2: How do I determine the correct density of EVA foam for my project?

- Q3: Is EVA foam environmentally friendly and recyclable?

- Q4: Can EVA foam be used for outdoor applications?

- Q5: What are the advantages of opting for custom processing from my EVA foam supplier?