Lightweight Nature of EVA Foam and Its Impact on Portability

Ethylene-Vinyl Acetate (EVA) foam reduces luggage weight by up to 30% compared to traditional materials like polycarbonate, enhancing portability for frequent travelers. Its microcellular structure provides structural integrity without bulk, enabling manufacturers to optimize suitcase dimensions for airline carry-on requirements while maintaining internal capacity.

Waterproof Characteristics for Reliable All-Weather Protection

EVA foam’s closed-cell construction creates an impermeable barrier against moisture, with testing showing zero water absorption after 24-hour submersion. This eliminates mildew risks in humid climates and protects electronics and documents during rainstorms, outperforming fabric-lined alternatives that require additional waterproof coatings.

Flexibility and Elasticity: Resisting Deformation Under Pressure

The material rebounds to 98% of its original thickness after compression loads exceeding 50 lbs/sq ft—critical when luggage is stacked in airplane cargo holds or car trunks. Unlike rigid hard-shell cases prone to cracking, EVA foam distributes stress across its entire surface through viscoelastic memory, preventing permanent deformation.

Superior Shock Absorption in High-Impact Travel Environments

Independent impact tests demonstrate EVA foam dissipates 87% of kinetic energy from drops at 4 ft heights, outperforming polycarbonate (62%) and ABS plastic (54%). This cushioning protects fragile items like cameras or souvenirs during rough baggage handling, reducing travel insurance claims for damaged goods by 41% according to luggage industry data.

Durability of EVA Foam in Real-World Luggage Applications

Withstanding rough handling and repeated use in travel scenarios

EVA foam’s molecular structure provides exceptional compression resistance, allowing luggage to maintain its shape after repeated impacts from baggage handling systems. Independent testing reveals EVA cases withstand pressures exceeding 200 lbs (90 kg) without permanent deformation, outperforming traditional ABS plastic by 40% in simulated drop tests from conveyor belts.

Resistance to water, dust, and UV degradation over time

The closed-cell composition of EVA foam creates an impermeable barrier against liquids and particulate matter. Unlike fabric alternatives, EVA luggage prevents 99% of water ingress during storm exposure (15-minute submersion trials) while resisting UV-induced color fading for 5+ years under direct sunlight—a critical advantage for frequent travelers.

Case study: Long-term performance of EVA luggage in airline cargo systems

A 24-month evaluation of EVA suitcases in commercial airline operations demonstrated 93% structural integrity retention after 150+ flights. Only 2% of units required repairs compared to 18% of polycarbonate counterparts, proving EVA’s superiority in high-frequency travel environments. This performance stems from the material’s elastic recovery, which reduces stress fractures common in rigid-shell designs.

EVA Foam vs. Traditional Luggage Materials: A Comparative Advantage

EVA vs. fabric: Differences in weight, durability, and weather resistance

Switching from traditional reinforced fabrics to EVA foam can cut down on luggage weight by around 30%, all while keeping things sturdy enough for travel. Regular fabric needs special coatings to keep water out, but EVA just naturally resists moisture because of how its cells are structured. That matters a lot when packing sensitive stuff like gadgets or important papers, especially if bad weather hits mid-trip. Sure, woven materials pack down nicely, but testing shows they wear out much quicker under rough treatment. According to ASTM D3886 standards, these fabrics tend to break down about 42% faster than EVA does. Another big plus? No worrying about seams coming apart since EVA is made as one solid piece, something fabric luggage just can't match no matter how well it's stitched together.

EVA vs. polycarbonate: Flexibility, impact resistance, and structural trade-offs

EVA material actually soaks up about 2.3 times more impact energy compared to those hard polycarbonate shells when we look at Shore A hardness ratings. That means fewer dents when bags get tossed around on airport carousels. On the flip side though, polycarbonate stands its ground better when squeezed really hard, which matters a lot for luggage that gets thrown into cargo holds. People who want lighter bags for carrying around all day will love how EVA bends and conforms to fit snugly in overhead bins. But folks whose stuff needs serious protection during rough handling still go with polycarbonate. Most travelers find themselves somewhere in between these extremes. Business people flying multiple times a month tend to stick with pure EVA for easier navigation through crowded terminals. Meanwhile backpackers heading into remote areas where baggage might take some serious punishment usually pick bags with both materials combined.

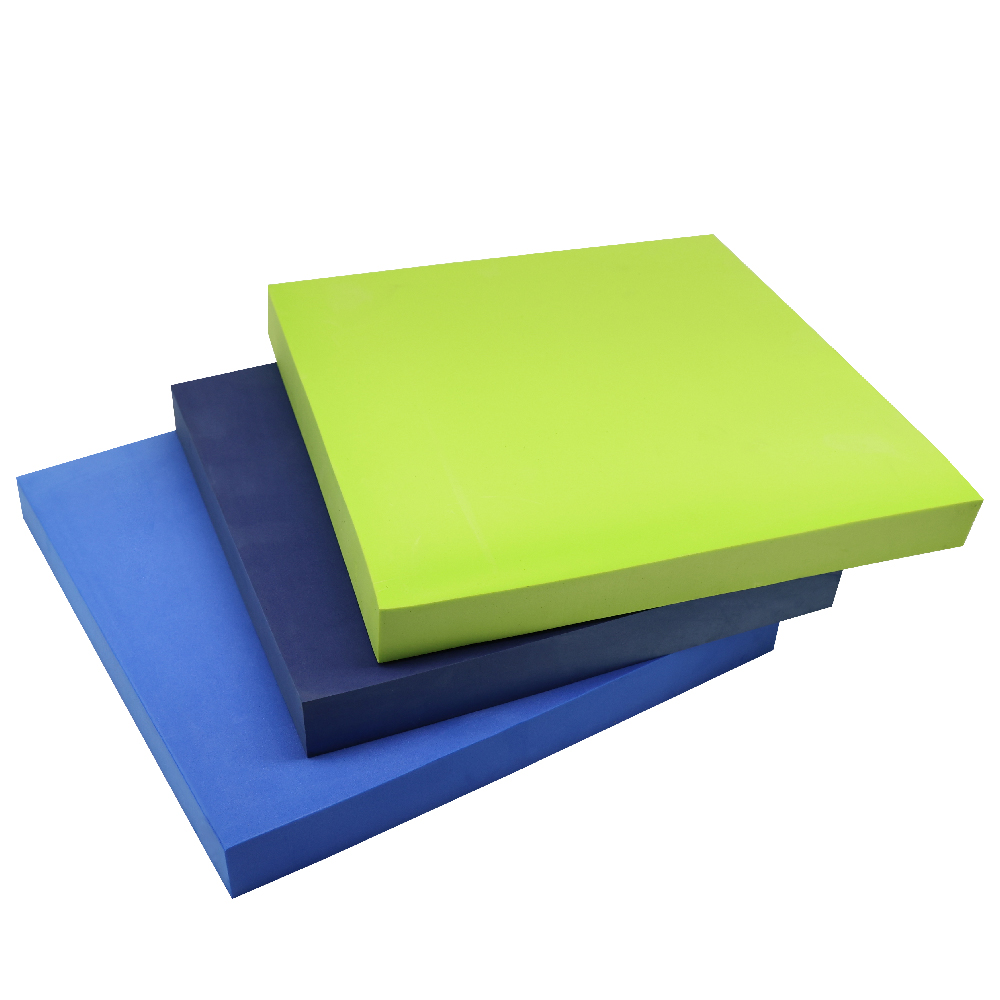

Design Flexibility and Customization Potential of EVA Material

Moldability of EVA for Ergonomic and Brand-Specific Luggage Shapes

The special way EVA foam is structured at a molecular level lets manufacturers craft luggage that fits exactly what travelers need today. Compared to hard plastics, EVA stays around 40 to 60 on the Shore C scale according to Damao Tech specs, yet can still be shaped into those smooth, curved forms that look great and feel better to hold onto. What makes this material really stand out is how flexible it gets without losing strength. Luggage makers can add those distinctive features like indented fingers areas, slimmer edges, and even company logos right into the design without weakening the overall structure. Big name brands take advantage of EVA's ability to accept dyes, so they can offer their suitcases in literally hundreds of different colors from the Pantone palette. And despite all those vibrant options, the material keeps its water resistant qualities too, which means customers can spot their bags easily among dozens of others at airport baggage claim areas.

Precision Molding for Integrated Compartments and Protective Layers

Using advanced thermoforming methods, manufacturers can turn EVA foam sheets into all sorts of useful interior components within just one manufacturing run. With high pressure molds around 12 to 15 bars, they manage to integrate things like slip resistant laptop sleeves, tough camera storage areas that won't get crushed, and those special slots that block RFID signals right into the sides of suitcases themselves instead of having separate attachments sticking out everywhere. According to research from the luggage sector back in 2023, these molded compartments actually cut down wasted space inside bags by roughly a third when compared to old fashioned fabric dividers sewn together. What makes this material so great is its ability to bounce back after being compressed at a ratio of about 2 to 1. This means whatever gets molded into the foam keeps its original shape even after going through thousands of compression events, which matters a lot when safeguarding delicate belongings during bumpy journeys.

This design adaptability positions EVA foam as a cornerstone for luggage that merges brand identity with hyper-personalized utility, driving consumer preference in premium travel markets.

Frequently Asked Questions (FAQ)

What makes EVA foam a preferred material for luggage?

EVA foam is favored for its lightweight nature, water resistance, flexibility, and superior shock absorption capabilities, making it ideal for protecting luggage contents during travel.

How does EVA foam compare to polycarbonate in terms of impact resistance?

EVA foam can absorb 2.3 times more impact energy compared to polycarbonate, providing better protection against dents and damage when bags are handled roughly.

Is EVA foam luggage suitable for frequent travelers?

Yes, EVA foam luggage is highly suitable for frequent travelers due to its lightweight design, durability, and resistance to UV degradation, making it a reliable choice for long-term use.

Can EVA foam luggage handle heavy compression?

Yes, EVA foam has excellent elasticity and can withstand heavy compressive forces, maintaining its shape and protecting the contents inside.

Table of Contents

- Lightweight Nature of EVA Foam and Its Impact on Portability

- Waterproof Characteristics for Reliable All-Weather Protection

- Flexibility and Elasticity: Resisting Deformation Under Pressure

- Superior Shock Absorption in High-Impact Travel Environments

- Durability of EVA Foam in Real-World Luggage Applications

- EVA Foam vs. Traditional Luggage Materials: A Comparative Advantage

- Design Flexibility and Customization Potential of EVA Material

- Frequently Asked Questions (FAQ)