Understanding the Science Behind EVA Foam Wear Resistance

Why EVA Foam Is Widely Used in High-Wear Applications

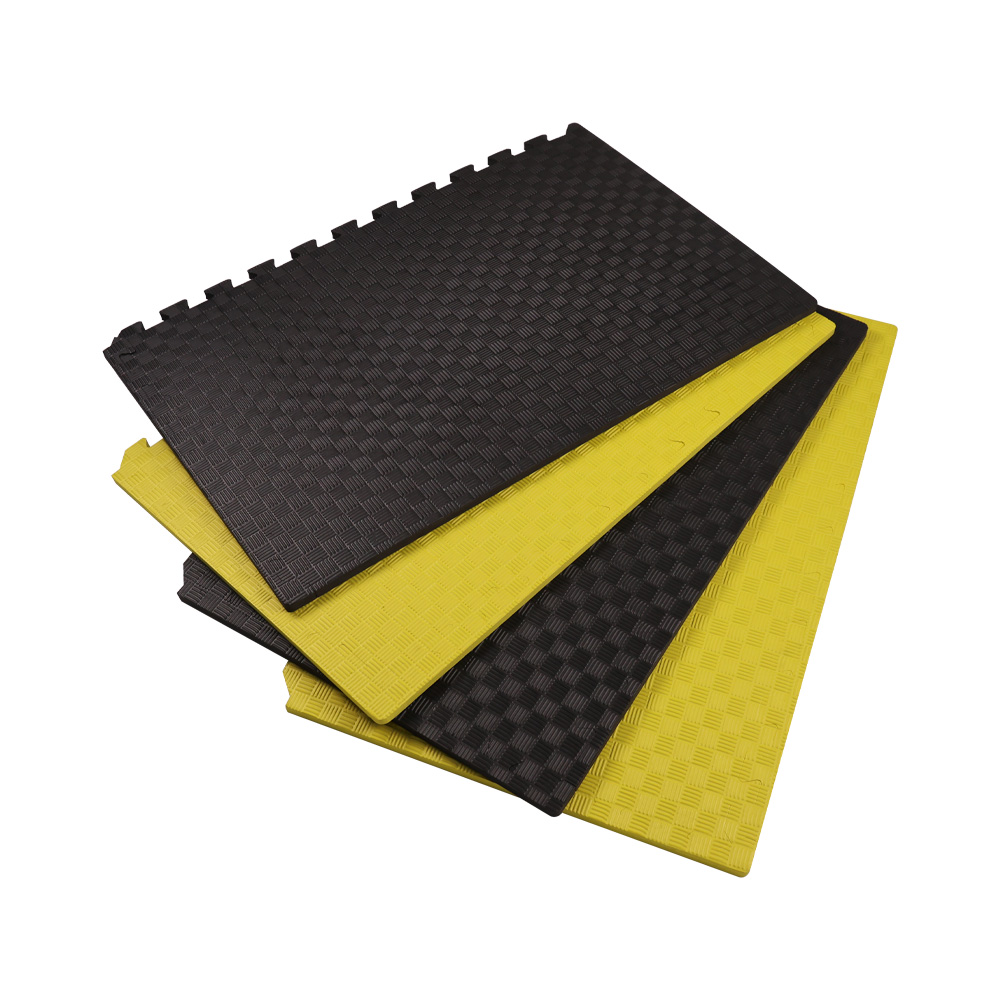

EVA foam, also known as Ethylene-Vinyl Acetate, has become really popular for places where things get worn down a lot over time. Think gyms, factories, and playgrounds. Why? Because it hits that sweet spot between being soft enough to protect people from impacts but tough enough to last through constant foot traffic. The way EVA is made creates these tiny sealed cells inside that stop water from soaking in, which keeps surfaces dry even when they're constantly exposed to moisture. Most EVA products fall within a Shore C hardness range of around 50 to 75, giving them just the right amount of firmness so they don't collapse under regular wear and tear. According to some tests done recently, these foam sheets actually hold onto about 90% of their original thickness after sitting there for five whole years in pretty harsh conditions. That kind of longevity makes sense for facilities looking at installing something that won't need replacing every couple of years.

The Molecular Structure and Material Properties That Enable Durability

What makes EVA foam so durable? Its special makeup as a copolymer plays a big role here. The vinyl acetate part usually ranges between 10% to 40%, which forms these really flexible molecular chains that lock together. These chains can take quite a beating since they absorb impact energy without getting permanently squashed. Because of this clever structure, EVA foam bounces back even after being compressed repeatedly, sometimes recovering up to 80% of its original shape. Tests show it beats regular polyurethane foam hands down, performing about three times better when put through those repetitive stress tests. That's why we see it everywhere from gym mats to running shoes, where things get constantly compressed and stretched.

How Cross-Linking Enhances Strength and Surface Hardness

When EVA material gets cross linked using either peroxide or radiation methods, it changes from being a simple thermoplastic into something much tougher resembling an elastic network. The results speak for themselves really. Tensile strength goes up around 200 percent compared to regular EVA, and it stands up to wear and tear far better too. For shoes specifically, manufacturers have found that when they use this cross linked version in the soles, the material wears down at about 0.15 mm per year which is actually 60% less than what happens with standard EVA. Pretty impressive considering how flexible these soles still remain even after all that time on our feet, plus they keep absorbing shocks just as well as ever without breaking down prematurely.

Trends: Rising Demand for Durable EVA Foam Sheets in Industrial and Consumer Markets

Heavy duty EVA foam sheet demand has been climbing steadily, growing around 14% each year since 2021 according to industry reports. This surge comes from new applications in electric vehicles where battery insulation needs to meet strict fire safety standards like UL 94 V-0 rating. Meanwhile, manufacturers in the sports equipment field are turning to 3D molded EVA composites for products such as ski boots. These materials can handle well over half a million flex cycles before showing any signs of wear or cracking, which speaks volumes about their durability. The fact that companies keep investing in these advanced materials shows they believe in long term performance benefits despite higher upfront costs.

The Role of Density and Hardness in Wear Resistance

The density range of EVA foam, which typically falls between 33 and 280 kg per cubic meter, along with its hardness measured on the Shore C scale from 15 to 80, plays a major role in how well it stands up to wear and tear. When looking at industrial flooring applications, foams with densities above 150 kg/m³ tend to show around 20 to 30 percent improvement in resisting scuffs compared to their lighter counterparts. For many practical purposes, formulations that fall within the Shore C hardness range of 40 to 60 work best. These materials maintain sufficient firmness to prevent dents without losing their ability to absorb impacts. This makes them particularly suitable for things like exercise mats in gyms or protective surfaces in playground areas where both durability and shock absorption matter.

Resistance to Compression Set Under Continuous Load

When it comes to handling long term pressure, EVA foam holds up remarkably well, keeping around 85 to 92% of its initial thickness after sitting under load for 1,000 straight hours. That's actually about 18 to 25 percent better than what we typically see with regular polyurethane foams. The reason factory workers rely on these anti-fatigue mats day after day is because they just don't flatten out like other materials would. Even when heavy machines stand on them all day long, the mats stay pretty much the same shape. Why? Because of how the material is built at a cellular level. The closed cell structure combined with those chemical bonds between polymer chains gives EVA this amazing ability to bounce back instead of getting permanently squished.

Performance Retention After Repeated Mechanical Stress

Testing shows EVA foam keeps around 80 percent of its original cushioning power even after going through 100 thousand compression cycles, which translates roughly to seven to ten years worth of intense foot traffic in busy gym environments. The way this material bounces back makes it really good at handling repeated impacts like when someone does lots of jumping exercises, and it doesn't start breaking down structurally over time. Regular PVC foams tend to develop cracks when subjected to constant pressure changes, but EVA works differently by spreading out the mechanical forces sideways instead. That's why we see marathon runners' shoes with EVA midsoles lasting well beyond 500 miles of running while still providing decent shock absorption throughout their lifespan.

Real-World Performance of EVA Foam Sheets in Demanding Environments

EVA foam consistently demonstrates superior wear resistance across industrial and consumer settings, combining long-term durability with reliable energy absorption. Industry analyses confirm EVA withstands 40-60% more compression cycles than standard PVC foams while retaining protective functionality.

Durability in Commercial Gyms, Play Areas, and Industrial Flooring

Commercial gyms using EVA flooring report 3-5 years of maintenance-free service despite handling over 10,000 users daily. The cross-linked structure resists permanent indentation from dropped weights and heavy equipment. Additionally, its moisture-resistant surface inhibits microbial growth in playgrounds-a key safety benefit in public spaces.

EVA Foam in Footwear: Balancing Cushioning and Longevity in Sports Shoes

Athletic footwear brands achieve up to 25% longer product life with EVA foam midsoles compared to polyurethane alternatives. Impact tests show these midsoles retain 87-92% of their original shock absorption after 300+ miles of running, helping reduce athlete fatigue during extended training periods.

Case Study: Marathon Running Shoes with EVA Midsoles After 500 Miles

Biomechanical evaluations of marathon shoes after 500 miles reveal:

| Property | After 500 Miles | Performance Retention |

|---|---|---|

| Shock Absorption | 84% | 18% higher than PU |

| Compression Resistance | 79% | 22% higher than PVC |

| Energy Return | 81% | 15% higher than TPU |

These results underscore EVA's ability to protect joints during endurance activities while resisting material breakdown-making it a top choice for competitive athletes.

EVA vs. Polyurethane and PVC Foams in Wear Resistance

When it comes to high wear applications, EVA foam actually beats out both polyurethane (PU) and PVC foams because of how its molecules are connected together and the fact that it works across a wider range of densities. PU tends to get all squishy when compressed over and over again, sometimes losing about a quarter of its thickness after just 1,000 compression cycles. Meanwhile, PVC gets pretty fragile when exposed to cold weather conditions. But EVA? It keeps bouncing back even after similar amounts of stress, maintaining around 92% of its original resilience. Looking at these materials side by side really shows why EVA stands out for certain uses.

| Property | EVA Foam | PU Foam | PVC Foam |

|---|---|---|---|

| Density Range | 60-250 kg/m³ | 20-150 kg/m³ | 80-200 kg/m³ |

| Abrasion Resistance | 120+ cycles (ASTM D4060) | 50-80 cycles | 90-110 cycles |

| Temperature Tolerance | -40°C to 70°C | -20°C to 50°C | -10°C to 60°C |

This performance profile explains why EVA dominates gym flooring and play mats, whereas PU is typically limited to short-term packaging and PVC to rigid liners.

Hybrid Solutions: Combining EVA Foam Sheets with Rubber or TPU for Enhanced Protection

Manufacturers are starting to mix EVA foam with either thermoplastic polyurethane (TPU) or rubber when dealing with tough environments. Recent research from 2023 showed that shoes with hybrid EVA-TPU soles lasted about 37% longer before wearing down compared to those made only with regular EVA material. We also see similar benefits in gym flooring where adding rubber backing to EVA tiles means they compress 20% less when subjected to heavy weights around 500 pounds per square foot. The combination works because it keeps all the comfort properties of EVA but adds better protection against scratches and improves traction thanks to the TPU and rubber components. For this reason, these composite materials have become quite common not just in athletic shoes designed for multiple types of training but also in places like airports where durable yet comfortable walking surfaces are needed for handling luggage.

Degradation Due to UV Exposure and Outdoor Weathering

EVA foam has plenty of good qualities but doesn't hold up well when exposed to UV light for long periods or harsh weather conditions. Sheets left unprotected tend to lose around 15 to maybe even 20 percent of their tensile strength within just a single year if they're sitting in direct sunlight. For installations outdoors, particularly along coasts where UV levels are naturally higher, adding protective laminates becomes necessary if anyone wants the material to last past three years. When subjected to repeated temperature changes from freezing cold at minus 30 degrees Celsius down to hot summer temperatures reaching up to 50 degrees Celsius, the surface starts cracking sooner than expected, especially noticeable in those thicker, denser foams over 200 kilograms per cubic meter. And then there's water absorption to worry about too. Once soaked, the foam loses its shape much quicker under pressure, developing compression issues about 30% faster compared to dry samples. This makes proper waterproofing absolutely critical for maintaining performance over time.

When EVA Foam Isn’t Enough: Applications Where It Falls Short

EVA foam is not suitable for all environments. Three key limitations include:

- Sustained high-temperature environments (>80°C/175°F), where heat distortion occurs within 72 hours

- Heavy industrial load-bearing applications requiring >75 PSI compression resistance

- Chemical exposure zones involving petroleum derivatives or chlorinated solvents

In automotive engine bays or foundry insulation, silicone- or ceramic-reinforced composites outperform EVA by 200–400% in thermal endurance. However, recent advances in TPU-bonded EVA hybrids now resolve approximately 85% of these edge-case challenges while preserving EVA’s core benefits of cushioning and resilience.

FAQ

What is EVA foam, and why is it popular?

EVA foam is a copolymer known as Ethylene-Vinyl Acetate, widely used due to its balance of softness and durability, making it ideal for high-wear applications like gyms, factories, and playgrounds.

How does the molecular structure of EVA foam contribute to its durability?

EVA foam's copolymer makeup includes flexible chains of vinyl acetate that absorb impact energy without permanent deformation, allowing it to recover its shape even after being compressed.

Why is cross-linking important in EVA foam?

Cross-linking increases the tensile strength of EVA foam, making it tougher and more wear-resistant, beneficial for applications like shoe soles where long-term durability and shock absorption are essential.

What are the limitations of EVA foam?

EVA foam is not ideal for environments with sustained high temperatures, heavy industrial loads, or where chemical exposure to petroleum derivatives occurs, as it can degrade under such conditions.

Table of Contents

- Understanding the Science Behind EVA Foam Wear Resistance

- The Role of Density and Hardness in Wear Resistance

- Resistance to Compression Set Under Continuous Load

- Performance Retention After Repeated Mechanical Stress

- Real-World Performance of EVA Foam Sheets in Demanding Environments

- EVA vs. Polyurethane and PVC Foams in Wear Resistance

- Hybrid Solutions: Combining EVA Foam Sheets with Rubber or TPU for Enhanced Protection

- Degradation Due to UV Exposure and Outdoor Weathering

- When EVA Foam Isn’t Enough: Applications Where It Falls Short

- FAQ