PP Supercritical Foaming Materials: Which Industries Benefit the Most?

From soft to hard, low to high elasticity, micro-pore to ultra-thick foam, when we discuss the application boundaries of PP supercritical foaming technology, the 45 years of industry experience held by the SANSD Group acts like a technological mirror, reflecting the multifaceted role of this technology across various sectors.

As part of the SANSD Group with over 45 years of experience, we are not only a global leader in the manufacturing of EVA, PE, EPDM, and TPE foam materials but also seasoned practitioners of supercritical foaming technology.

This precise technology involves permeating polymers with supercritical fluids under specific temperature and pressure conditions, followed by rapid depressurization to induce expansion, thereby forming a unique microcellular structure.

From sports shoes to packaging materials, toys to gym mats, marine decking to industrial applications, the scope of PP supercritical foaming materials continues to expand, bringing revolutionary performance enhancements to various industries.

01 Technical Core: Understanding the Essence of Supercritical Foaming

Supercritical foaming is a physical foaming technology that utilizes fluids in a supercritical state as blowing agents. When a fluid reaches its supercritical state, it possesses both gas-like diffusivity and liquid-like density, allowing it to efficiently permeate the polymer matrix.

The core principle of PP supercritical foaming involves precisely controlling temperature and pressure to inject the supercritical fluid into the molten or solid polymer. A rapid pressure drop then causes the dissolved fluid within the polymer to expand, forming a fine closed-cell foam structure.

This process yields materials with distinctive performance characteristics. Compared to traditional chemical foaming, physical foaming eliminates chemical residues, resulting in purer, more environmentally friendly products. The microcellular structure provides the material with lightweight properties, high rebound, and excellent cushioning performance.

Based on our practical experience, adjusting process parameters allows for precise control over cell size and distribution, enabling the customization of material properties to meet the specific needs of different application fields.

02 Synergistic Effects: A Comparison of TPU and EVA Material Foaming

In the application of supercritical foaming technology, TPU and EVA are two materials with distinct yet equally important characteristics. Understanding their differences helps industries select the most suitable material solution.

TPU Supercritical Foaming materials are renowned for their excellent wear resistance, oil resistance, and mechanical strength. After supercritical foaming treatment, TPU materials develop a uniform microcellular structure, significantly reducing density without sacrificing their inherent physical properties.

In contrast, EVA Supercritical Foaming materials exhibit different characteristic advantages. EVA itself possesses good flexibility, elasticity, and weather resistance. After foaming, its cushioning performance and lightweight effect are further enhanced. EVA foamed materials perform particularly well in shock absorption and comfort.

Within our product line, drawing on over 45 years of SANSD Group experience, we fully leverage the characteristic strengths of both materials.

For applications requiring high rebound and wear resistance, we recommend TPU foamed materials; for scenarios prioritizing comfort and lightweight properties, EVA foamed materials become the ideal choice.

03 Footwear Revolution: The Fusion of High Rebound and Extreme Lightweight

The footwear industry is one of the most extensive and in-depth fields for the application of supercritical foaming technology, particularly in the athletic shoe market. Traditional midsole materials like EVA, while offering certain advantages in lightweight and cushioning, still have performance limitations.

PP Supercritical Foaming Technology brings revolutionary breakthroughs to footwear design through its unique microcellular structure. Compared to traditional EVA, supercritically foamed midsoles offer higher rebound rates, lighter weight, and greater durability.

TPU Supercritical Foaming materials also hold an irreplaceable position in the footwear industry. TPU's high wear resistance and good mechanical strength make it a premium choice for outsole materials.

After foaming, TPU outsoles not only retain their wear-resistant characteristics but also gain improved cushioning and lighter weight.

The SANSD Group possesses profound experience in the footwear materials sector. Our EVA shoe materials have long been recognized for their lightness, comfort, excellent cushioning, flexibility, and durability.

By introducing supercritical foaming technology, our footwear material products have achieved further performance upgrades, meeting diverse needs from sports and casual shoes to outdoor footwear, children's shoes, slippers, and safety shoes.

04 Innovative Packaging: The Perfect Balance of Lightweight and Cushioning Performance

In the packaging industry, PP supercritical foaming materials are redefining the standards for protective packaging. Traditional packaging materials like EPS and PU foam have limitations in cushioning and environmental friendliness, while supercritical foaming technology offers a superior solution.

The advantages of the microcellular structure are evident, allowing the material to provide stronger protection with less material usage, reducing transportation costs and energy consumption.

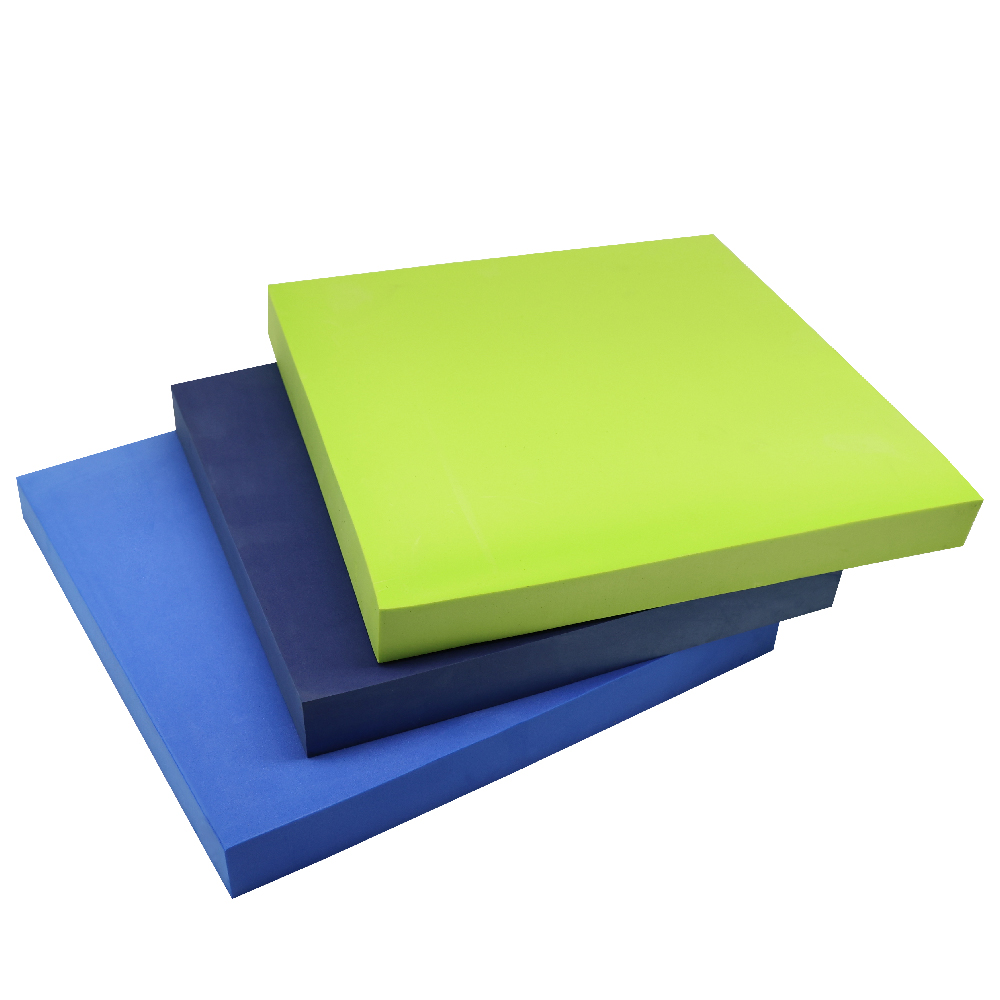

Supercritical foaming materials hold special value in electronics and cosmetics packaging. Based on our product experience, second-stage EVA foam offers high hardness, low density, light weight, and reasonable pricing. Its good stability makes it easy to clean and customize.

Regarding environmental protection, PP supercritical foaming materials demonstrate clear advantages. Unlike traditional chemical foaming materials, the physical foaming process does not use chemical blowing agents, and the material itself can be recycled, complying with increasingly stringent environmental regulations and consumer expectations.

05 Sports Equipment: Innovation from Yoga Mats to Gym Equipment

In the sports equipment field, the application of PP supercritical foaming materials is rapidly expanding. Traditional sports mats and equipment often use conventional foam materials, which have limitations in comfort, durability, and performance.

Supercritical foaming technology is changing this scenario. By precisely controlling cell structure and material density, the foamed material can provide optimal cushioning and rebound performance.

In products like yoga mats, EVA supercritical foaming materials showcase unique advantages. Our EVA foam sheets are designed for superior cushioning and flexibility, providing a perfect foundation for various applications.

High rebound and shock absorption enhance comfort while protecting against impact. Anti-wear and tear-resistant properties ensure long-lasting performance.

In the fitness equipment sector, TPU supercritical foaming materials also play a significant role. TPU's high strength and wear resistance make it an ideal choice for gym mats, protective pads, and equipment components.

06 Industrial Applications: Automotive, Marine, and Specialized Industries

The application of PP supercritical foaming materials in the industrial sector demonstrates its potential as a versatile material. From automotive interiors to marine decking, industrial gaskets to specialized packaging, this material provides unique solutions.

The automotive industry is a major application area for PP supercritical foaming materials. In automotive interior parts, seat cushions, and acoustic insulation materials, supercritical foaming materials can offer composite functions of lightweight, sound insulation, and vibration damping.

The marine field also benefits from supercritical foaming technology. Marine decking materials require waterproofing, corrosion resistance, and good cushioning performance.

Through their closed-cell structure and material stability, supercritical foaming materials can resist seawater erosion and provide a safe, comfortable deck surface.

For industrial gaskets and seals, TPU supercritical foaming materials are highly regarded for their oil resistance and mechanical strength. Foamed TPU materials not only retain their original chemical resistance but also gain compressibility and sealing effectiveness.

07 Design Possibilities: Diverse Processing from Sheets to Custom Shapes

The value of supercritical foaming materials lies not only in their inherent physical properties but also in their excellent processability, which is a key factor in their widespread application across different industries.

The diversity of SANSD Group's product line fully demonstrates the processing flexibility of supercritical foaming materials.

From oversized foam boards, rolls, and mats to molded products like yoga mats and slippers, along with various custom processing options, we can meet the specific needs of different industries.

Custom processing capabilities are a significant driver for the expanded application of supercritical foaming materials. Through cutting, molding, fabric/leather lamination, drilling, and other processes, basic foamed materials can be transformed into custom products suitable for specific applications.

Cross-industry adaptability is a notable advantage of supercritical foaming materials. Whether in sporting goods, toys, packaging, luggage, marine decking, or various industrial applications, this material can be transformed into valuable components through appropriate processing.

08 Sustainable Future: Eco-Friendly Materials and the Circular Economy

In today's business environment that prioritizes sustainable development, the environmental characteristics of PP supercritical foaming materials are becoming a key advantage. Traditional foaming materials often face challenges in recyclability and environmental persistence.

The physical foaming process itself offers environmental benefits. Unlike chemical foaming, physical foaming does not use chemical blowing agents, eliminating potential harmful substance residues.

Material recyclability is another environmental highlight of supercritical foaming materials. Through appropriate recycling processes, foamed materials can be repurposed, reducing resource waste.

Energy efficiency is also a noteworthy aspect of supercritical foaming materials. In application, their lightweight properties reduce transportation energy consumption; in construction and industrial applications, their thermal insulation properties help decrease energy usage.

From the fine structure of microcellular foam to the industrial application of oversized foam boards, from the flexibility of EVA to the strength of TPU, supercritical foaming technology is redefining the possibilities of foam materials. This technology is not only about material science but also about how various industries can achieve a future that is lighter, stronger, and more environmentally friendly.

With continuous technological advancements and expanding applications, we can foresee that from high-end sports equipment to everyday consumer goods, from precision electronics packaging to heavy-duty industrial applications, supercritical foaming materials will permeate more fields, driving industries toward a more lightweight, efficient, and environmentally friendly direction of continuous evolution.

Table of Contents

- PP Supercritical Foaming Materials: Which Industries Benefit the Most?

- 01 Technical Core: Understanding the Essence of Supercritical Foaming

- 02 Synergistic Effects: A Comparison of TPU and EVA Material Foaming

- 03 Footwear Revolution: The Fusion of High Rebound and Extreme Lightweight

- 04 Innovative Packaging: The Perfect Balance of Lightweight and Cushioning Performance

- 05 Sports Equipment: Innovation from Yoga Mats to Gym Equipment

- 06 Industrial Applications: Automotive, Marine, and Specialized Industries

- 07 Design Possibilities: Diverse Processing from Sheets to Custom Shapes

- 08 Sustainable Future: Eco-Friendly Materials and the Circular Economy