In today's increasingly competitive global market, fast and efficient product prototyping is not just an advantage but a necessity. For brands across various industries such as footwear & apparel, sporting goods, packaging, and consumer goods, the choice of prototyping material directly impacts the development cycle, cost-effectiveness, and the final product quality. Among the many available materials, EVA foam stands out due to its exceptional properties, making it the material of choice for prototyping. As the global leader under the Sansd Group with over 40 years of advanced foam manufacturing experience, our company, Quanzhou Weifu Foam Trade Co., Ltd., deeply understands the critical role EVA foam plays in transforming concepts into tangible, testable prototypes. This article will not only explain why EVA foam is the ideal prototyping material but also delve into how the Sansd Group is pioneering an ecologically circular future for EVA materials through innovative melting/thermal separation recycling technology. It will combine academic perspectives to provide brands with prototyping solutions that balance performance and sustainability.

Understanding EVA Foam: The Ideal Prototyping Material

Ethylene-Vinyl Acetate (EVA) foam is a closed-cell, flexible material renowned for its unique combination of properties: lightweight, durable, with excellent cushioning, shock absorption, and vibration isolation. Its wide range of density, hardness (from soft to rigid), and elasticity can be precisely tailored to simulate the performance characteristics of many end-use materials.

This versatility is invaluable to brands. Whether you're developing a new insole for athletic footwear, a protective pad for fitness equipment, a custom insert for product packaging, or a marine deck component, EVA foam can be engineered for specific prototyping needs. Its closed-cell structure also makes it waterproof, non-hygroscopic, and easy to clean—crucial for testing in various environments.

Strategic Advantages of Using EVA Foam for Prototyping

1. Speed and Flexibility in Development

Prototyping phases are often time-critical. EVA foam facilitates rapid iteration. It is highly amenable to various custom fabrication techniques like precision die-cutting, CNC milling, hot wire cutting, and molding. This enables design teams to quickly produce multiple physical versions, test form, fit, and function, and implement design modifications without lengthy delays or prohibitive costs.

2. High Cost-Effectiveness

Prototyping with metals, certain plastics, or specialty composites can be expensive, especially for small batches. EVA foam offers a cost-effective alternative without compromising the ability to evaluate critical design aspects. Its affordability allows brands to allocate resources more effectively across multiple design cycles.

3. Functional Fidelity

A prototype should not just look like the final product; it should perform like it. The mechanical properties of EVA foam—such as compressibility, resilience, and density—can be finely tuned. This means a yoga mat prototype can accurately simulate the desired grip and cushioning, while a suitcase pad prototype can demonstrate real-world impact protection. This functional fidelity leads to more reliable test data and better-informed decisions.

4. Ease of Modification and Finishing

Design changes are inherent to prototyping. EVA foam is easy to laminate, bond, and finish. Through our advanced lamination services, it can be seamlessly combined with fabrics, leathers, or other materials to create composite prototypes highly resembling the final assembled product. Processes like drilling, embossing, or surface texturing can also be applied to achieve specific aesthetic or functional goals.

Sansd's Environmental Commitment: Melting/Thermal Separation and EVA's Eco-Recyclable Loop

While pursuing prototyping performance, the Sansd Group actively practices environmental responsibility, committed to driving a closed-loop cycle for EVA materials. The melting/thermal separation method we employ is an efficient recycling and regeneration technology for EVA foam.

This technology uses controlled thermal energy input to melt waste EVA material in an oxygen-free or low-oxygen environment, effectively separating and removing impurities while maximally preserving the integrity of the EVA polymer chains. The recycled EVA pellets processed through this method can be reused to manufacture various foam products with stable performance, significantly reducing reliance on virgin resin.

Academic Research Support: As experts in the field of polymer circular economy point out, "For cross-linked foamed polymers like EVA, traditional mechanical recycling often faces challenges of performance degradation. However, technologies like targeted de-crosslinking or melting/re-pelletizing, similar to thermal separation, can reconstruct the material at a molecular level, representing an effective pathway for its high-value recycling." (Cited from "Review on Technological Advances in Polymer Material Recycling"). Sansd's process puts this concept into practice, diverting waste EVA from potential landfills and reintegrating it into the production cycle, significantly reducing carbon footprint and resource consumption.

This offers brands a forward-looking choice: opting for EVA material with a "recyclable DNA" even at the prototyping stage, injecting environmental principles into the product's entire lifecycle, and responding to the global call for sustainable development.

Cross-Industry Applications: From Concept to Reality

The applications of EVA foam in prototyping are nearly limitless, mirroring its use in final products.

Footwear & Sporting Goods: Prototype midsoles, insoles, ankle collars, or tongue pads for athletic shoes. Test cushioning systems for exercise mats or protective gear.

Consumer Goods & Toys: Create safe, durable prototypes for children's toys, puzzle floor mats, or cosplay components. Its non-toxic nature makes it suitable for these sensitive applications.

Packaging & Display: Design and test custom protective packaging inserts for electronics, luxury goods, or medical devices. Evaluate foam performance in protecting products during simulated transit.

Industrial & Marine: Develop prototypes for sealing gaskets or anti-vibration pads. Simulate marine deck components, testing for buoyancy, slip resistance, and underfoot comfort.

Luggage & Fashion: Simulate padding for bags and luggage, or prototype components for slippers and fashion accessories.

Partnering with a Professional Foam Manufacturer

The success of a prototyping project often hinges on the material supplier's expertise. Not all EVA foam is created equal. Factors like consistency, density tolerance, and surface quality are critical. As part of the Sansd Group, we bring unparalleled technical knowledge and quality control.

We offer:

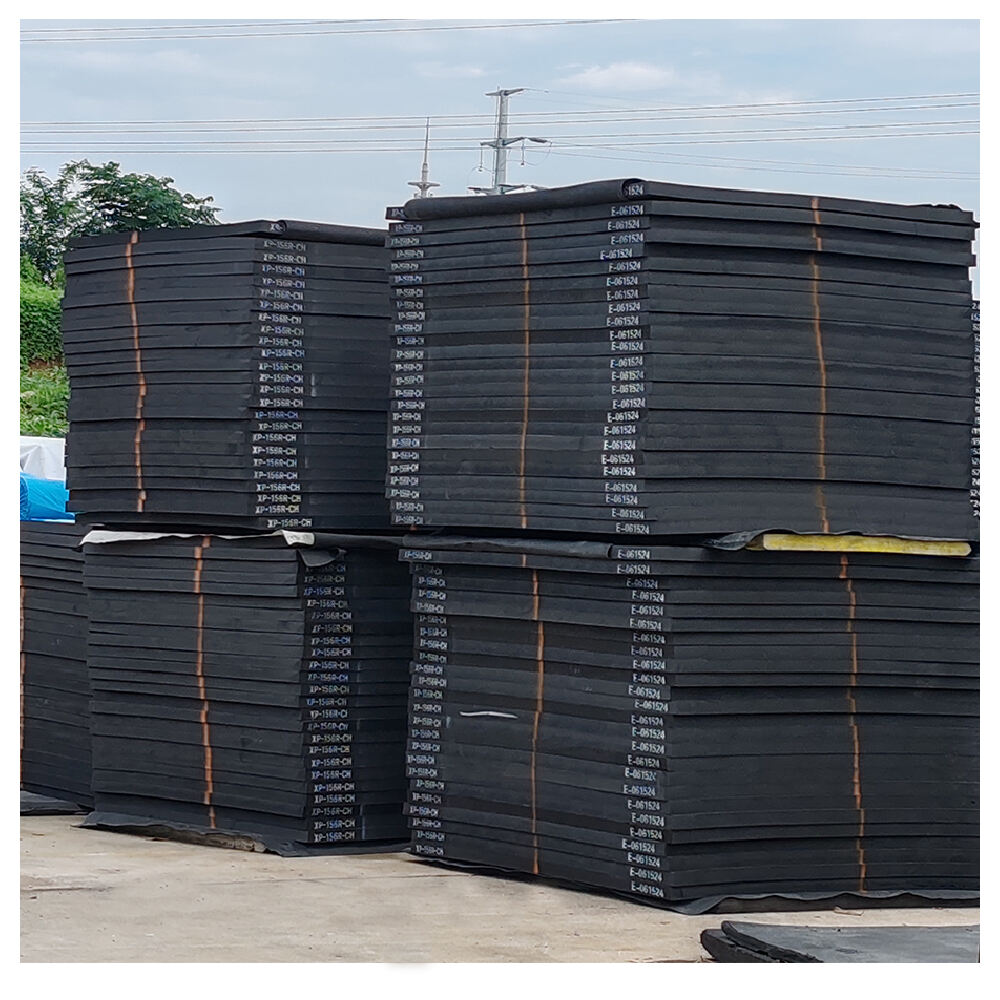

Diverse Prototyping Materials: From microcellular to ultra-thick EVA foam sheets/rolls, as well as alternative materials like PE foam, EPDM foam, and TPE foam for comparative testing.

Comprehensive Custom Fabrication Services: We support your prototyping journey with in-house cutting, molding, fabric/leather lamination, and drilling services. This vertical integration ensures quality and confidentiality at every step.

Technical Collaboration: Our team works with your designers and engineers to select the optimal foam grade and fabrication method, helping to de-risk the development process and accelerate time-to-market.

Conclusion

Adopting EVA foam for prototyping is a strategic decision that aligns with modern brands' needs for speed, flexibility, and cost-controlled innovation. Its unparalleled versatility and performance make it the material of choice for transforming visionary ideas into tangible realities ready for evaluation and refinement.

At Quanzhou Weifu Foam, we are more than a supplier; we are an innovation partner. Leveraging over 40 years of expertise in EVA foam, PE foam, EPDM foam, and TPE foam, combined with industry-leading melting/thermal separation recycling technology, we empower not only your prototyping phase but also lay a solid and sustainable foundation for your product's success.

Visit our website at www.wefoameva.com to explore our capabilities and start your next prototyping project with a world-class foam solutions partner.

Frequently Asked Questions (FAQs)

Q1: What are the key performance differences between EVA foam and PE foam for prototyping?

A: Both are excellent closed-cell foams but serve different purposes. EVA foam generally offers greater flexibility, elasticity, and a softer feel, making it ideal for applications requiring cushioning and comfort, like insoles or yoga mats. PE foam (polyethylene) is often more rigid and offers better chemical resistance, providing superior impact absorption for heavy-duty protective packaging or industrial applications. The choice depends on the specific mechanical and tactile properties your prototype requires.

Q2: How customizable is EVA foam for complex prototype shapes?

A: EVA foam is highly customizable. Through processes like precision die-cutting (for 2D shapes), CNC milling or hot wire cutting (for complex 3D contours), and compression or injection molding (for high volumes or detailed parts), we can produce virtually any shape. Combined with post-processing like lamination or drilling, complex multi-component prototypes can be created.

Q3: Can EVA foam prototypes be used for functional performance testing?

A: Absolutely. This is one of the greatest strengths of EVA foam in prototyping. By selecting the correct density, hardness, and elasticity grades, prototypes can be engineered to perform under specific stress, compression, or impact conditions. This makes them suitable for functional testing in applications ranging from sports performance (like midsole energy return) to protective packaging drop tests.

Q4: What are the benefits of laminated EVA foam in prototypes?

A: Lamination bonds a layer of fabric, leather, or other material onto the EVA foam. In prototyping, this is crucial for testing the final product's look, feel, and performance. For instance, a laminated prototype for luggage or slippers allows designers to assess aesthetics, grip, abrasion resistance, and how materials interact as a system before finalizing production specifications.

Table of Contents

- Understanding EVA Foam: The Ideal Prototyping Material

- Strategic Advantages of Using EVA Foam for Prototyping

- Sansd's Environmental Commitment: Melting/Thermal Separation and EVA's Eco-Recyclable Loop

- Cross-Industry Applications: From Concept to Reality

- Partnering with a Professional Foam Manufacturer

- Conclusion

- Frequently Asked Questions (FAQs)