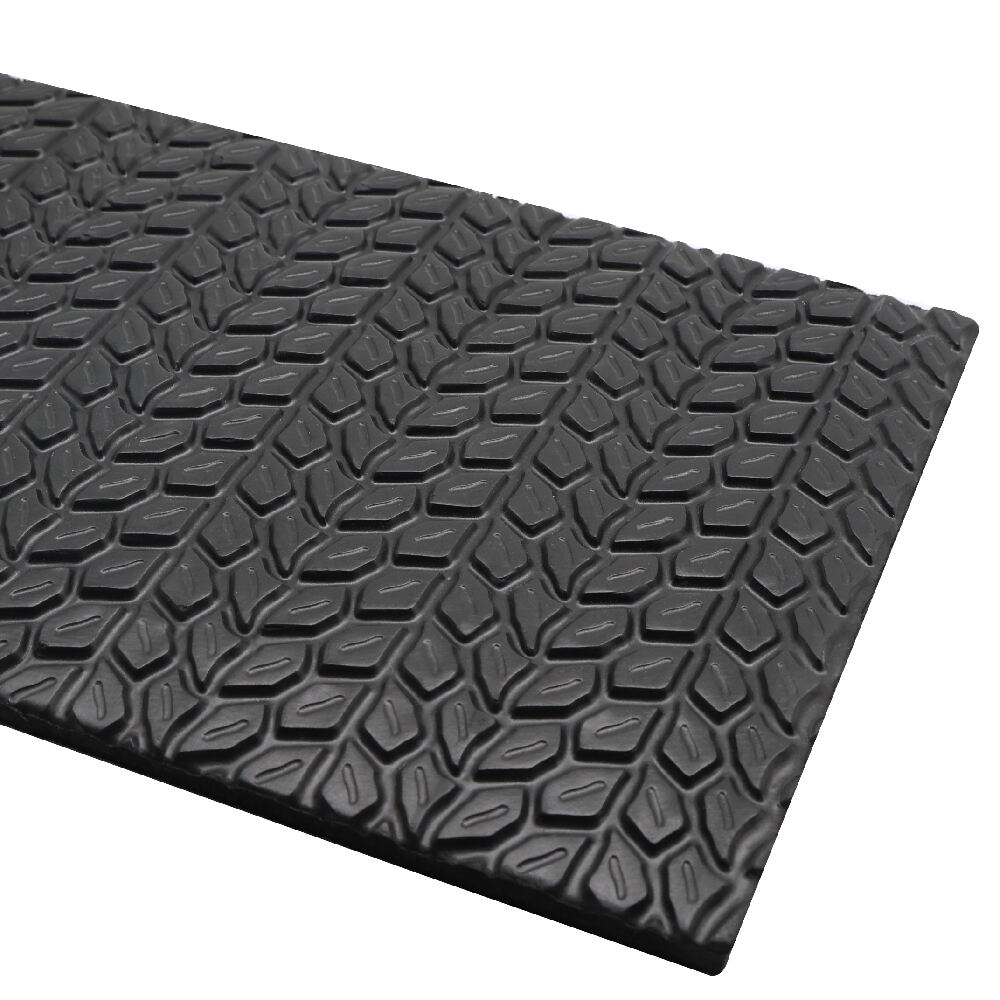

Shoes manufacturing materials form the foundation of footwear production, encompassing a vast array of substances chosen for their specific properties and functions. Leather, a timeless choice, is prized for its durability, flexibility, and natural aesthetic. Different types of leather, such as full-grain, top-grain, and corrected-grain, offer varying levels of quality and performance, with full-grain leather being the most durable and premium. Synthetic materials, including PVC, TPU, and EVA, have revolutionized the industry with their affordability, versatility, and ease of customization. PVC is often used for shoe soles due to its excellent abrasion resistance and low cost, while TPU provides enhanced shock absorption and stability, making it ideal for athletic footwear. EVA, known for its lightweight and cushioning properties, is widely used in midsoles and insoles, offering comfort and support. Textile materials like nylon and polyester are commonly employed for shoe uppers, providing breathability and flexibility. Additionally, materials such as rubber, foam, and adhesives play crucial roles in the manufacturing process. Rubber is essential for outsoles, providing traction and grip, while foams like PU and EVA contribute to cushioning. Adhesives ensure the secure bonding of different components, ensuring the structural integrity of the shoes. The selection of these materials depends on various factors, including the intended use of the shoes, design requirements, and cost considerations, with manufacturers constantly exploring new materials and technologies to improve the performance and quality of their products.