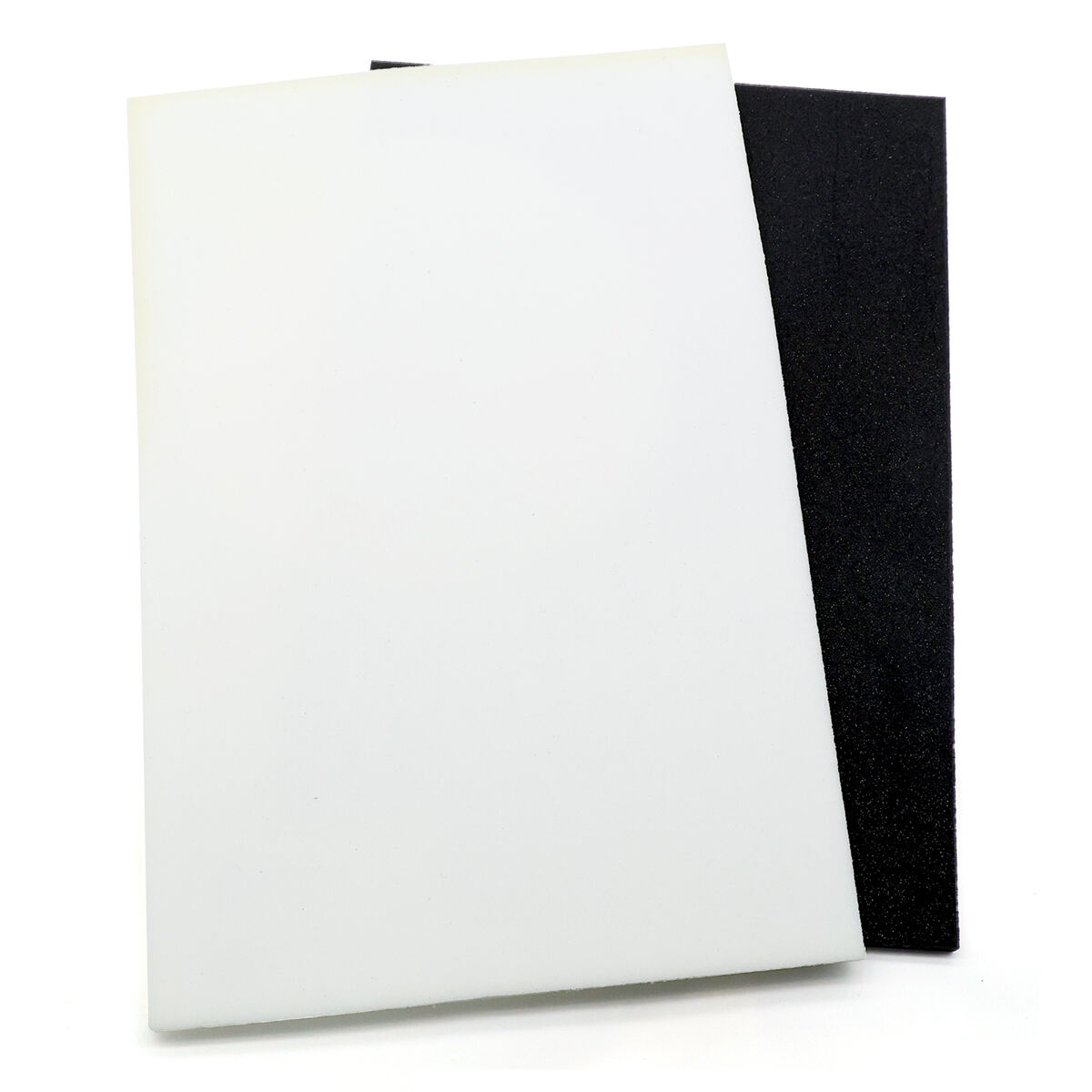

Custom cut PU foam caters to unique project requirements through precision fabrication, making use of advanced cutting technologies like waterjet, CNC routers, or die-cutting to achieve intricate shapes and exact dimensions. This service starts with material selection—ranging from soft, low-density foams for cushioning to high-density variants for structural support—followed by computer-aided design (CAD) to translate specifications into executable patterns. Common applications include tailored packaging inserts, ergonomic furniture padding, and specialized automotive components, where exact fit and performance are necessary. Manufacturers ensure consistency through quality control measures like density testing and dimensional verification, offering clients flexibility in foam type, thickness, and surface finishing to meet both functional and aesthetic requirements. Whether it's a complex geometric shape or a specific size, custom cut PU foam can be tailored to meet the exact needs of the project.