The Sports Footwear Revolution: EVA’s Core Advantage

In the competitive world of athletic footwear, EVA foam has redefined performance standards. Unlike rigid rubber soles or heavy polyurethane, EVA strikes an unbeatable balance—its closed-cell structure traps air pockets that compress on impact, then rebound with remarkable efficiency. This unique elasticity translates to a "bouncy" feel that elite athletes crave, as every stride converts energy into forward motion rather than wasted vibration. Shoe designers now engineer EVA midsole patterns with precision, using 3D modeling to map pressure points; runners notice how the foam cushions heels during landing while firming up under toes for powerful takeoffs. Even casual wearers benefit: EVA’s lightweight nature ensures that marathoners don’t feel weighed down during 26.2 miles, while weekend hikers appreciate how it resists water absorption, keeping shoes from turning soggy on rainy trails. Major brands have capitalized on this versatility, showcasing EVA in everything from minimalist running shoes to chunky "dad sneakers," proving its appeal spans across styles and sports.

Beyond the Laces: EVA’s Industrial Takeover

While sports shoes put EVA in the spotlight, its industrial applications reveal its true adaptability. Manufacturers value its resistance to oils, chemicals, and extreme temperatures—qualities that make it ideal for heavy-duty environments. In manufacturing plants, EVA sheets line conveyor belts to prevent scratches on delicate electronics, while its sound-dampening properties muffle the roar of machinery in assembly lines. The shipping industry relies on EVA’s shock-absorbing capabilities too: fragile items like medical equipment and glassware travel safely encased in custom-cut foam inserts that conform to their shapes, eliminating costly breakages. Even in construction, EVA foam acts as a buffer between metal components, reducing friction-induced wear and extending the lifespan of tools and structural parts.

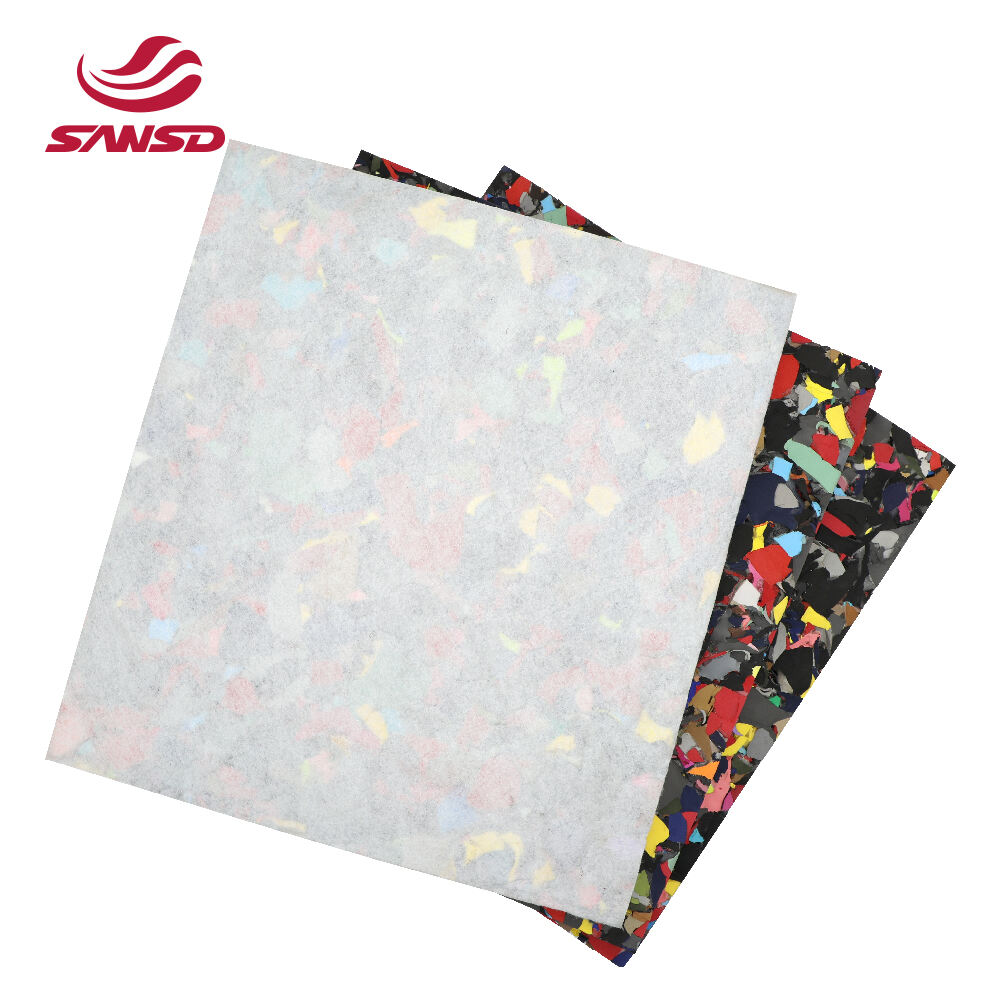

Sustainable Innovations: EVA Goes Green

As environmental consciousness reshapes consumer demands, the EVA foam industry is undergoing a sustainability makeover. Traditional production methods relied heavily on virgin plastics, but modern manufacturers are pioneering blends that incorporate up to 30% recycled materials—from post-consumer plastic bottles to industrial scrap. This not only cuts down on landfill waste but also reduces the carbon footprint of foam production by minimizing the need for raw petroleum-based inputs. Innovators are also experimenting with bio-based additives, replacing synthetic compounds with plant-derived polymers that maintain EVA’s performance while making it easier to decompose at the end of its lifecycle. Brands in both sports and industrial sectors are marketing these eco-friendly variants aggressively, with labels highlighting "recycled EVA" as a key selling point, bridging the gap between functionality and environmental responsibility.

Engineering the Future: Next-Level EVA Capabilities

Researchers are pushing EVA foam into uncharted territory with advanced modifications. Recent breakthroughs in cross-linking technology have created ultra-durable variants that withstand repeated compression without losing elasticity—critical for high-traffic applications like gym flooring and wheelchair cushions. Heat-resistant formulations are being tested for automotive underhood insulation, where EVA could replace heavier materials while withstanding engine temperatures. Additionally, nanotechnology is enabling the creation of EVA foams with tailored porosity, allowing precise control over breathability for use in protective gear like helmets and knee pads. These innovations aren’t just incremental improvements; they’re expanding EVA’s potential to disrupt industries from aerospace (as lightweight insulation) to healthcare (as hypoallergenic medical padding). As these technologies mature, EVA foam is poised to transition from a "go-to" material to an indispensable component in countless cutting-edge products.