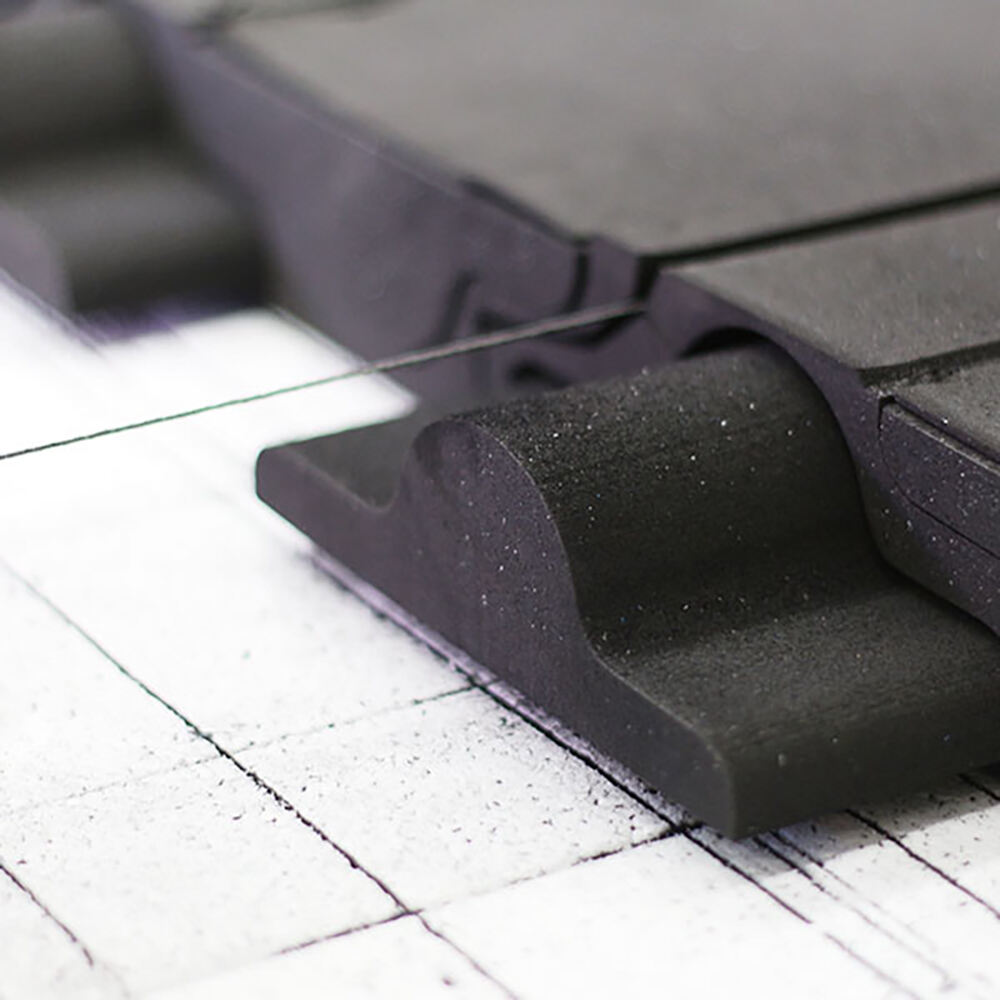

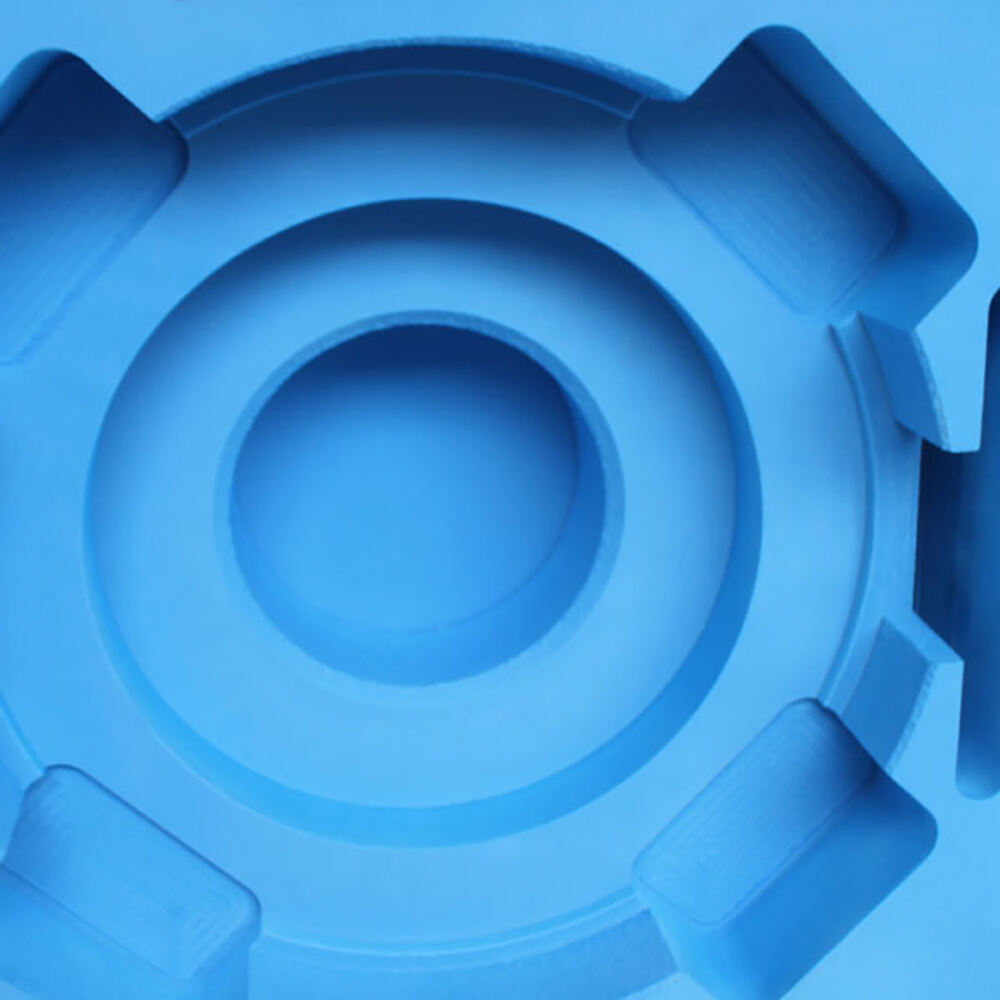

QUANZHOU WEFOAM TRADING CO., LTD, leveraging the extensive experience of the SANSD Group, offers unparalleled xlpe foam custom cutting services to meet the unique needs of clients across various industries. The company's state-of-the-art cutting technology, combined with a deep understanding of xlpe foam properties, enables precise and intricate cuts that adhere to the most demanding specifications. Whether it's die-cutting for creating complex shapes used in packaging inserts, CNC cutting for large-scale industrial components, or waterjet cutting for highly detailed and clean edges, QUANZHOU WEFOAM can handle it all. The xlpe foam custom cutting service is highly adaptable, accommodating different thicknesses of foam sheets, from thin layers used in acoustic panels to thick slabs for thermal insulation in construction projects. With skilled technicians overseeing the process and advanced quality control measures in place, each cut piece maintains the integrity and performance characteristics of the original xlpe foam, such as its insulation, cushioning, and durability. This custom cutting service, coupled with additional processing options like lamination and drilling, allows clients to transform xlpe foam into tailor-made solutions for applications ranging from automotive interiors and sports equipment to aerospace components.