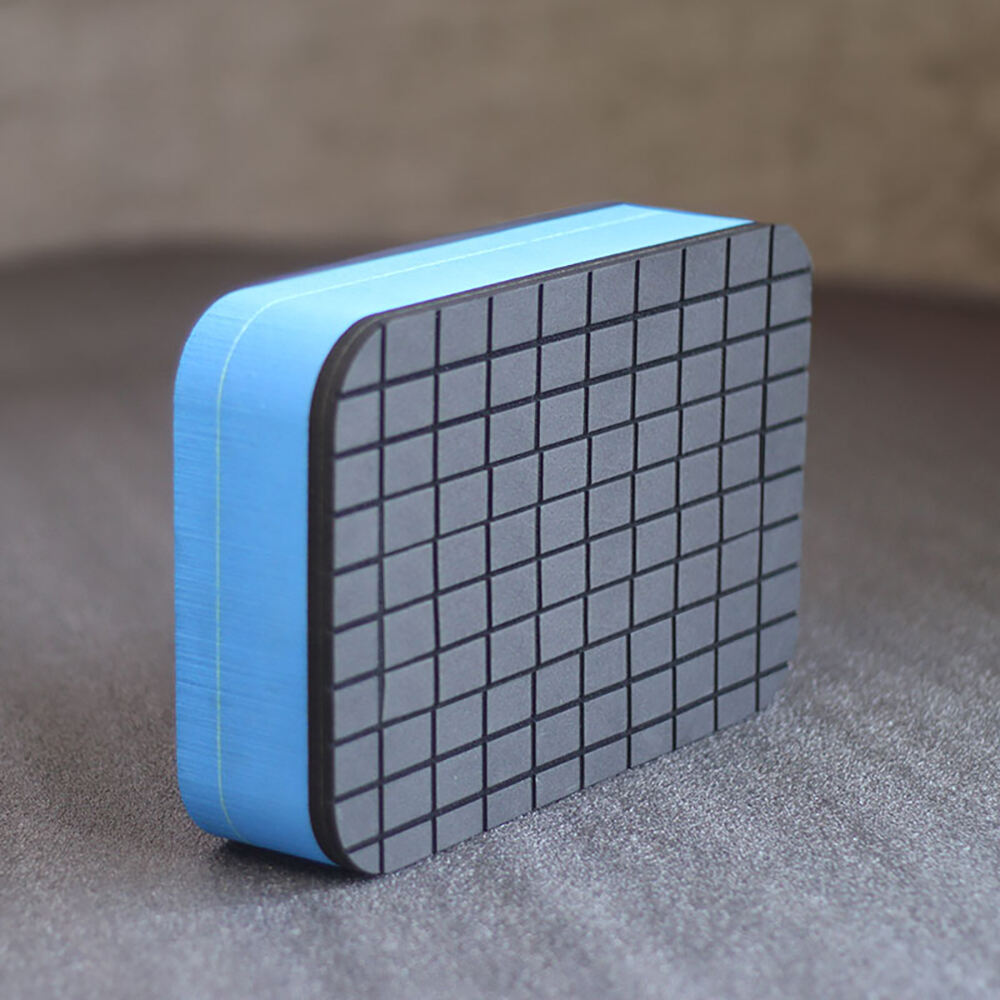

PE foam for packaging has revolutionized the protective packaging industry with its lightweight yet robust properties. Made from polyethylene, a thermoplastic polymer, this foam offers a unique combination of cushioning, shock absorption, and durability. Its open-cell or closed-cell structure, depending on the application requirements, provides excellent resistance to impacts, vibrations, and scratches, ensuring the safe transit of products. PE foam's low density reduces shipping costs while still providing effective protection, making it a cost-effective solution for businesses across various sectors. In electronics packaging, its anti-static properties prevent damage to sensitive components from electrostatic discharge, safeguarding products like computers, smartphones, and delicate electronic parts. For fragile items such as glassware, ceramics, and artwork, PE foam's soft texture and conformability create a snug fit, minimizing movement within the packaging. The foam can be easily customized through cutting, die-cutting, and shaping processes to accommodate different product shapes and sizes. Moreover, its resistance to moisture and chemicals ensures that products remain protected even in challenging storage and transportation conditions. With an increasing focus on sustainability, many PE foam for packaging solutions are now recyclable, aligning with environmentally friendly practices in the industry.